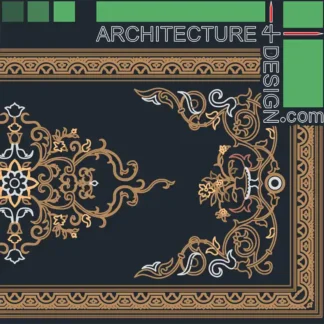

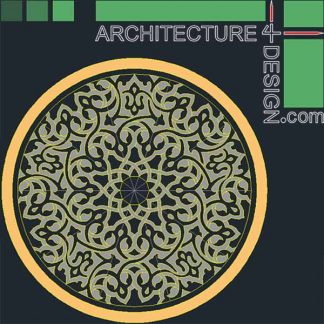

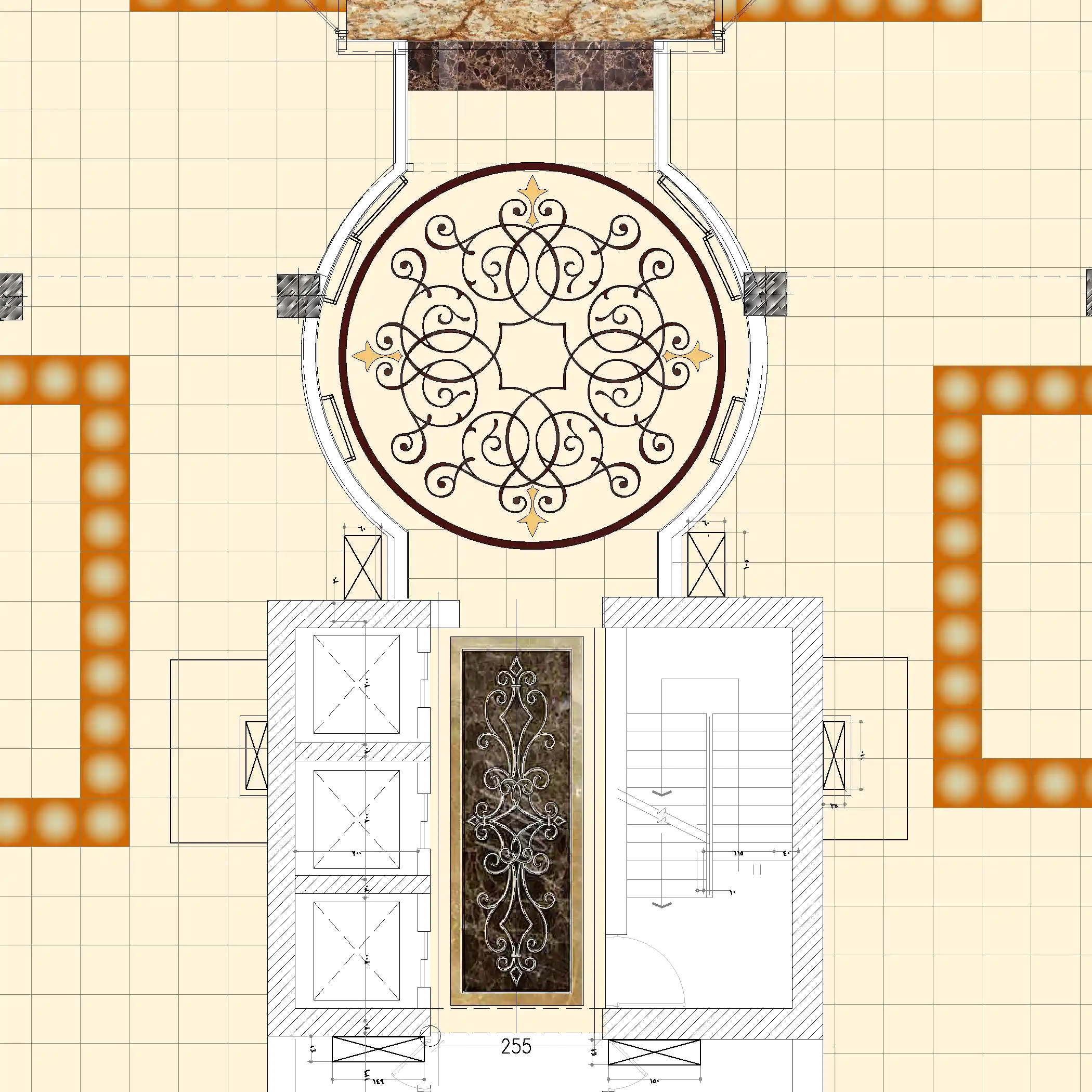

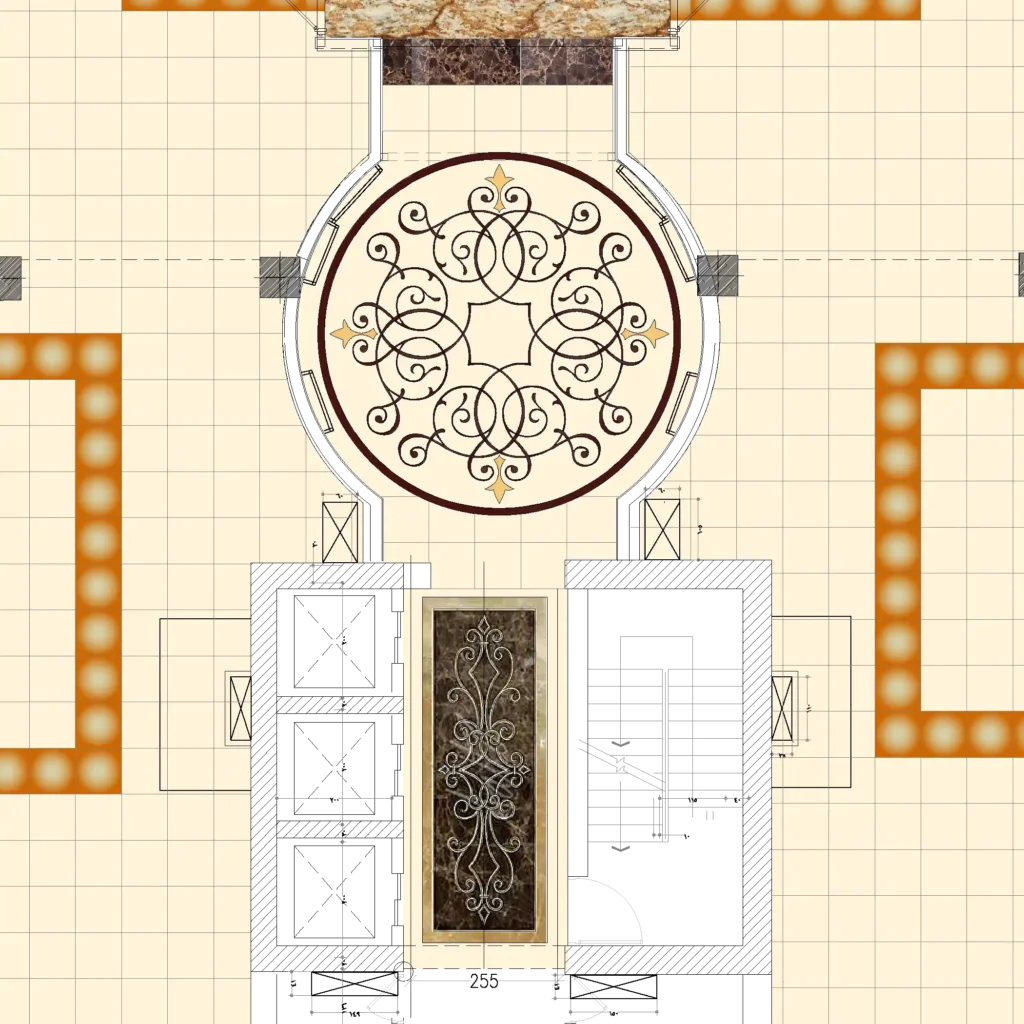

Magnificent flooring with waterjet inlay

Flooring design is an essential aspect of interior design. It is one of the most important elements that can transform a space and create a unique atmosphere. The right flooring design can elevate a room’s aesthetic appeal, create a warm and inviting ambiance, and increase the value of a property.

Water jet cutting is a method of cutting materials like stone, steel, brass, glass, ceramics, or aluminum using a high-pressure stream of water. This technique has become increasingly popular in floor design, as it allows for precise cuts and intricate designs to be created on a variety of flooring materials.

One of the most significant advantages of water jet cutting in floor design is the ability to create intricate and unique patterns. Traditional cutting methods may limit the complexity of designs that can be created, but water jet cutting allows for more intricate designs with a high degree of accuracy. The ability to create intricate patterns makes water jet cutting an ideal choice for high-end residential and commercial spaces, as it adds a unique touch of sophistication to the flooring design.

Another advantage of water jet cutting is that it can be used on a wide range of flooring materials, including stone, tile, and hardwood. This versatility makes it an excellent choice for both indoor and outdoor spaces, as it can be used to create beautiful designs on patios, decks, and other outdoor areas. Additionally, water jet cutting can be used on various thicknesses of materials, allowing for design possibilities in materials that may otherwise be difficult to cut.

In terms of sustainability, water jet cutting is an eco-friendly option for flooring design. Unlike traditional cutting methods, water jet cutting does not produce any hazardous waste, and it requires less energy to operate. Additionally, the use of water in the cutting process means that it can be recycled and reused, reducing water consumption in the manufacturing process.

One of the few potential drawbacks of water jet cutting in flooring design is that it can be more expensive than traditional cutting methods. The machinery used in water jet cutting is highly specialized, and the cost of the equipment is reflected in the cost of the final product. However, the precision and versatility of water jet cutting make it an excellent choice for high-end projects that require intricate designs.

Water jet cutting is an excellent choice for floor design, particularly in high-end residential and commercial spaces. Its ability to create unique and intricate patterns, versatility across a range of materials, and sustainability make it an attractive option for those looking to add a touch of sophistication to their flooring design. While the cost of water jet cutting may be higher than traditional cutting methods, the precision and beauty of the final product make it a worthwhile investment for those seeking a truly unique and eye-catching flooring design.